高中毕业后在家等了一年,和75届同学一起劳动了一年,又做了几个月的临时工,终于在76年末的时候,我被分到了另一个塑料厂做正式学徒工,14块钱一个月的学徒工资。这个厂规模不是很大,有大约400工人。产品是单一的聚氯乙烯树脂(粉状)。原材料是来自隔壁的化工厂。我不太懂得整个生产的工艺和流程。但一进厂你就会很清楚地看到这实际上是个化工厂,自动化程度较高(相对而言),到处都是管道。是个24/7连班倒的工厂。工人们都上三班。我们一起进厂的有二十来人。来自市里各个高中。我们高中有6-7个一起分去的(我的高中是全市最大的中学之一)。一起分去的都是75届高中毕业生,比我小一届。但非常幸运的是有两个同班一起在商场老动的同学也分在这个厂,总算有两个认识的人。

我被分到电工班。电工班有十来个工友(师傅)。因为厂不大,电工班强电,弱电都做。也很有意思,可以学到很多东西。强电工作包括拉电线,竖电线杆子,给车间安装或维护配电版,修马达。弱电包括安装,维修电子仪表,更换机械压力表。我们工作中的电压从3.5万伏高压,到工业用电的三相380伏,到民用电的220伏,到仪表上的3伏,12伏直流电,什么都有。

我们有五个学徒工分到电工班(比例是很高的了)。三个做强电,一个做弱电,我被要求两面都做做。这样一来我有两个师傅。一个做强电,爬电线杆,拉电线,做配电版。另一个师傅是弱电,修仪表,换电子器件,等等。

我在厂里工作时间不长,一年多一点。有几件事情印象很深。这里先写两件。还有几件另外写。

一件事是我工作不久,和我师傅一起值夜班。我们通常是分成两班。白班一般是早八点到下午4:30。晚班一班是从大家走了一后,好像是4点一直到第二天早8点。电工因为晚上活不多。一班就两个人。上一次这样的班就休息一天。大家轮流上夜班。夜班期间一般定期到各车间转转,一般没有什么事。我们经常在后半夜可以在变电房里睡一会儿。有一天我们正在变电房里躺着,突然跳闸。全厂停电。我们可以听到跳闸的巨响(3.5万伏变压器)。这时我们的任务是立刻把闸推上。厂里流水线是不能停电的。我师傅年轻,也没见过这阵势。两个人只好硬着头皮上。穿好特别的绝缘靴子,带好特别的绝缘手套,拿好绝缘棒,因为我们要操作的是3.5万伏变压器。要是触了电,顿时化为灰烬!还好,我师傅一下就把闸给推上了。两人都松了一口气。

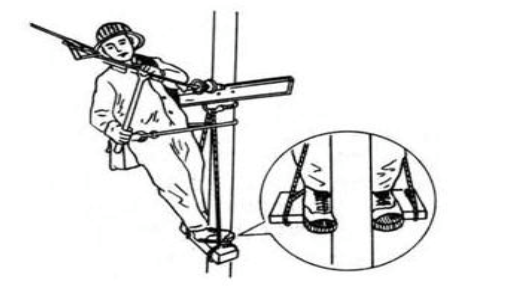

第二件事是学会爬电线杆。做电工有很多基本技术。爬杆是其中之一。那时的电线大多都架在电线杆上,谓之明线。我们学徒做电工,首先要学会爬杆。一般是师傅先演示,我们就试着学。爬杆一般有两种方法。一种是用两只脚钩,另一种是用两块踏板。用脚钩上杆比较方便,快捷。但如果长时间站在电线杆上工作,会比较累,不舒服。另一种是用踏版。用踏板爬杆比较麻烦。每次站稳在一块版上后,把另一块板拿到上方合适的距离地方,固定住,再往上爬。上了一级后,要把下面以块板拿上去,重复以往,慢且不方便。但是当站在杆顶工作时,特别是较长时间的工作,感觉上要比脚钩舒服地多。我们几个学徒都在不长的时间里学会了爬杆。印象最深的是全电工班一起为厂里架设一条全新的高压线路(1.1万伏)。大家站在电线杆顶上工作了好几天。

First Full Time Job!

After waiting a full year in home when graduating from high school, then working together with next class (Class 1975) for another year, plus a few more months working in a factory as a temp, I finally got a full time job in another plastic factory as an apprentice, earning 14 yuan a month. This isn’t a large factory, about 400 people. The single product was polyvinyl chloride resin (powders). The source materials came from the chemical plant next door. I don’t quite understand the entire process of the production. But you can tell this is a chemical plant. The factory has a relatively high degree of automation, pipes are everywhere. People work in 24/7 shifts. The workers on the production line work three-shifts. We had about 20 new prentice as a cohort. We came from many different high schools across the city. My high school had 6 or 7 in this group. (My high school was one of the biggest one in the city.) The group of 20 or so new prentice were all graduates of class of 1975, one year behind me. I felt fortunate that two others who worked with me in the department store the year before were in the group, I at least knew someone.

I was assigned to the electrician team for the factory. We had about a dozen of us. Because this was not a very large factory. The electricians would have to take care of everything electric or electronics. This was good in the sense that we can learn many different things. On the electric side of the work, we’d do run the electric wires, install poles, design and maintain the electric circuits and motors in the production lines. On the electronics side, we’d work on install, test, and maintain electronic devices, meters of various kinds, including mechanic ones in the production lines. The range of voltages we’d work on goes from 35K voltage on the high wires, to 380 voltage for the 3-phase motors, to 220 voltage for the lights, to the 3 voltage or 12 voltage for the electronic devices.

A total of five of us apprentice were assigned to the electrician team (this was a pretty large number, considering there were a total of a dozen or so in the team). Three were to work on the electrical side, one in the electronics side, I was supposed to work on both. As such, I had two supervisors. One on the electrical side where we’d climb electrical poles, run wires, build electric distributors. The other supervisor was on the electronics side. He’d teach me electronics, soldering, measuring, and other things.

I worked in this plant for only slightly longer than a year. I learned a great deal and there were many stories I could write about. Here are two stories. I can write others at a different time.

Not to long after I started working, my supervisor and I were on duty for a all-night shift. The way it worked was that all of us would be at the day shift that runs from 8 in the morning to 4:30 in the afternoon. Everyday, there would be two of us who’d work for the night shift from 4:30 to 6:30 in the morning. The night shift was really meant to take care of emergency. That is, the night shifts didn’t need to build anything new. Usually it was quiet during the evening and night — there wasn’t much to do. We’d go around the plant for a few times, checking to make sure everything was running smoothly (usually it was). Then usually late in the night (early in the morning), we’d be able to lay down in the main transformer room for a while for some rests. One night while we were laying down there, the transformer jumped. We heard the loud “ban” noise from our main transformer (35 KV). All of sudden, everything was dark and all motors and production lines came to a full stop. Our task was to reset the circuits. My supervisor was relatively young, he never saw this before. We were trained and learned the routine to fix problems like this from the manual, but were never actually operated before. We were very nervous. We put on the special insulating boots and gloves. We’d use a special insulating pole to push the circuit to its “close” position. This was a 35 KV high voltage transformer. If we were electrified, we’d become ash instantly! My supervisor was ready to push the circuit, he asked me to stand aside to watch him and help him if needed (I wasn’t sure how I’d help him if something went wrong.) With his one firm push, the circuits was closed and the electricity was back! We were both relived.

The second thing I remembered well was to learn to climb the electrical poles. There are many basic skills as an electrician. On e of them is to be able to climb electrical poles. During those years, most of electrical wires were set on poles, called exposed wires (in today’s world, most wires or cables are underground.) To be an electrician, one has to learn how to climb these poles. Usually our supervisors would show us how to do it, we then would practice. They’d help us to get it right. There are usually two different ways of climbing a pole, one is to use two foot-hooks, the other to use a pair of boards. It is easier to climb with foot-hooks. It is almost like to “walk” up the poles with foot-hooks. The problem with these foot-hooks is that it is very tiring and uncomfortable if you stand and work at the top of the pole with foot-hooks only because the very small area that you can stand on. The climbing boards are difficult to use when climbing up. You’d have to tie one board first, stand on it, then tie the other one above you, climb to and stand on the top one, release the lower one. It is a slow and difficult process. But once at the top of the pole, it is much more comfortable to do work there with the boards, especially if you’d work for a long time at the top of the poles. All of us apprentice learned how to climb poles. I remember clearly what we did for a new electrical route of 11 KV high voltage. All of us, apprentice and supervisors worked at the top of the poles for days to run the wires from outside of the plant to the transformer room in the plant.